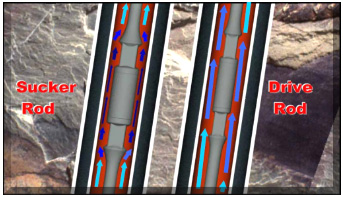

A sucker rod is a steel rod, typically between 25 and 30 feet (7 to 9 meters) in length, and threaded at both ends, used in the oil industry to join together the surface and downhole components of a reciprocating piston pump installed in an oil well.

Drive rod, which is made of high quality alloy steel, features special threaded connection and is manufactured using high quality processing technique, this could greatly lowers failure rate of sucker rods, thus reducing corresponding losses.

Specifications

| Inch Nominal Size | O.D. of Rod mm | In Nominal Diameter of the Thread | Width for the Spanner | Length | ||

| mm | Inch | mm | ft | |||

| ⅝ | 15.88 | 1 5/16 | 22.2 | ⅞ | 7518 9042 | 25 30 |

| ¾ | 19.05 | 1 1/16 | 25.4 | 1 | ||

| ⅞ | 22.23 | 1 3/16 | 25.4 | 1 | ||

| 1 | 25.40 | 1⅜ | 33.3 | 1 5/16 | ||

| 1⅛ | 28.58 | 1 9/16 | 38.1 | 1½ | ||

| Length of the pony rod: 20, 44, 68, 92, 116 inches | ||||||

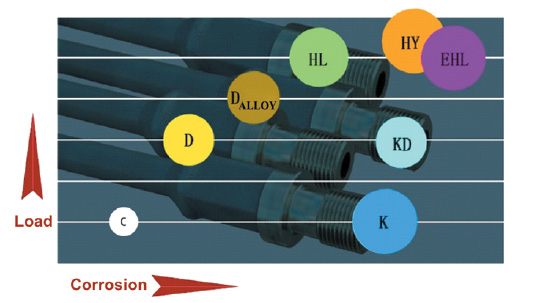

Selection Guide

| Mechanical Properties | ||||||||||

| Grade | Min. Yield Stregth | Min. Tensile Stregth | Max. Tensile Stregth | Elongation, 200mm, % | Reduction in Area, Z% | Surface Hardness, HRC | Core Hardness, HB | |||

| psi | Mpa | psi | Mpa | psi | Mpa | |||||

| K | 60,000 | 414 | 90,000 | 621 | 115,000 | 793 | ≥13 | ≥50 | ||

| C | 60,000 | 414 | 90,000 | 621 | 115,000 | 793 | ≥13 | ≥50 | ||

| D | 85,000 | 590 | 115,000 | 795 | 140,000 | 965 | ≥13 | ≥50 | ||

| KD | 85,000 | 590 | 115,000 | 795 | 140,000 | 965 | ≥13 | ≥50 | ||

| HL | 115,000 | 795 | 140,000 | 965 | 173,339 | 1,195 | ≥13 | ≥45 | ||

| HY | / | / | 140,000 | 965 | 173,339 | 1,195 | / | / | ≥42 | ≥224 |

| EHL | / | / | 188,500 | 1,300 | 217,500 | 1,500 | / | / | ≥50 | ≥320 |

| Chemical Properties | |||||||||||

| AISI | C | Si | Mn | P | S | Cr | Ni | Mo | V | Cu | AI |

| 1541 | 0.36-0.45 | 0.15-0.35 | 1.35-1.65 | ≤0.04 | ≤0.04 | ≤0.3 | ≤0.35 | ≤0.06 | 0.04-0.09 | ≤0.35 | ≤0.035 |

| 4120 | 0.17-0.24 | 0.17-0.37 | 0.4-0.7 | ≤0.025 | ≤0.025 | 0.8-1.1 | ≤0.3 | 0.15-0.25 | / | ≤0.2 | / |

| 4130 | 0.26-0.33 | 0.17-0.37 | 0.4-0.7 | ≤0.025 | ≤0.025 | 0.8-1.1 | ≤0.3 | 0.15-0.25 | / | ≤0.2 | / |

| 4138 | 0.37-0.45 | 0.17-0.37 | 0.9-1.2 | ≤0.025 | ≤0.025 | 0.9-1.2 | ≤0.3 | 0.2-0.3 | / | ≤0.2 | / |

| 4138M | 0.37-0.45 | 0.17-0.37 | 0.9-1.2 | ≤0.025 | ≤0.025 | 0.9-1.2 | ≤0.3 | 0.2-0.3 | 0.04-0.09 | ≤0.2 | / |

| 4140 | 0.38-0.45 | 0.17-0.37 | 0.5-0.8 | ≤0.025 | ≤0.025 | 0.9-1.2 | ≤0.3 | 0.15-0.25 | 0.04-0.09 | ≤0.2 | / |

| 4142 | 0.38-0.45 | 0.17-0.37 | 0.5-0.8 | ≤0.025 | ≤0.025 | 0.9-1.2 | ≤0.3 | 0.15-0.25 | 0.04-0.09 | ≤0.2 | / |

| 3130 | 0.22-0.29 | 0.15-0.35 | 0.71-1.0 | ≤0.025 | ≤0.025 | 0.42-0.65 | 0.72-1.0 | 0.01-0.06 | / | ≤0.2 | / |

| 4320 | 0.18-0.42 | 0.15-0.35 | 0.8-1.0 | ≤0.025 | ≤0.025 | 0.7-0.9 | 1.15-1.5 | 0.2-0.3 | 0.04-0.09 | ≤0.35 | ≤0.035 |

| 4330 | 0.3-0.35 | 0.15-0.35 | 0.8-1.1 | ≤0.025 | ≤0.025 | 0.8-1.1 | 1.65-2.0 | 0.2-0.3 | 0.05-0.10 | ≤0.2 | / |

| 4621 | 0.18-0.23 | 0.17-0.37 | 0.7-0.9 | ≤0.025 | ≤0.025 | ≤0.35 | 1.65-2.0 | 0.2-0.3 | / | ≤0.2 | / |

| 4720 | 0.19-0.23 | 0.15-0.35 | 0.85-1.05 | ≤0.025 | ≤0.025 | 0.8-1.05 | 0.9-1.2 | 0.22-0.30 | 0.02-0.05 | 0.40-0.60 | / |