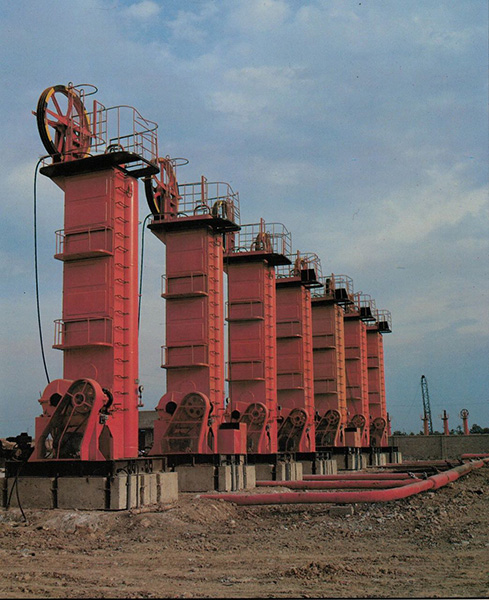

As a patent product of our company, VertiLift long stroke pumping unit have been applied in oilfield since 1984, and more than 3,000 sets of VertiLift pumping units have been installed in the oilfields of Sinopec, CNPC in China, as well as in Uzbekistan, Canada and Mexico.

VertiLift Pumping Units in 1980s Present Unit

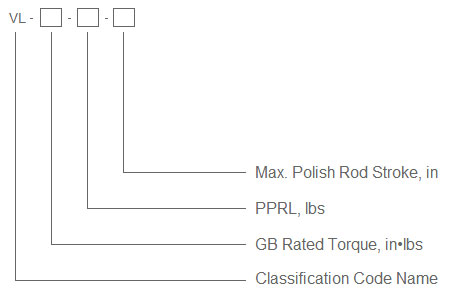

According to the differences of peak polish rod loads (PPRL) and gearbox rated torques and strokes, the VertiLift pumping units can be divided into 8 kinds of models.

| VL320-265-236 | VL320-309-276 | VL456-353-288 |

| VL456-353-315 | VL456-442-315 | VL456-486-315 |

| VL456-486-354 | VL640-617-315 |

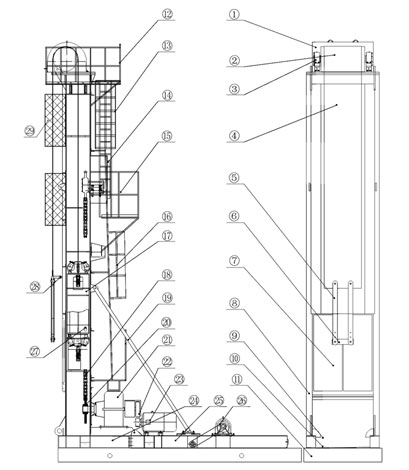

Parts Identification

| 1 | Hood | 9 | Lube oil Level Porthole | 17 | Counterweight Box | 25 | Skid |

| 2 | Top Drum | 10 | Lube oil Outlet | 18 | Chain | 26 | Roll-back System |

| 3 | Top Drum Bearing Assembly | 11 | Concrete Base | 19 | Standing Struts | 27 | Safety Pin |

| 4 | Load Belt | 12 | Top Platform | 20 | Drive Sprocket | 28 | Wind Wheel |

| 5 | Hanger Bar Connection Plate | 13 | Top Ladder | 21 | Gear Reducer | 29 | Wind Guards |

| 6 | Hanger Bar | 14 | Top Sprocket Enclosure | 22 | V-Belt/Belt Guard | ||

| 7 | Counterweight Doors | 15 | Mid Tower Platform | 23 | Prime Mover | ||

| 8 | Tower | 16 | Mid Ladder | 24 | Tower Base |

Specifications

| VertiLift Model | VL320-265-236 | VL320-309-276 | VL456-353-288 | VL456-353-315 | VL456-442-315 | VL456-486-315 | VL456-486-354 | VL640-617-315 |

| Reducer Rating (in·lb, kN·m) | 320000 37 | 456000 53 | 640000 73 | |||||

| Stroke Length (in, mm) | 236 6000 | 276 7000 | 288 7300 | 315 8000 | 315 8000 | 315 8000 | 354 9000 | 315 8000 |

| Maximum Polished Rod weight (lb, kg) | 26500 12000 | 30900 14000 | 35300 16000 | 44200 20000 | 48600 22000 | 61730 28000 | ||

| Maximum Strokes per Minute (SPM) | 4.5 | 4 | 4 | 3.5 | 3.5 | 3.5 | 3 | 3.5 |

| Minimum SPM | No absolute minimum for short term operation | |||||||

| Counterweight Assembly (lb, kg) | 6610 3000 | 7710 3500 | 8820 4000 | 8820 4000 | 11020 5000 | 11020 5000 | 11020 5000 | 13230 6000 |

| Auxiliary Counterweight (lb, kg) | 14330 6500 | 17640 8000 | 19840 9000 | 19840 9000 | 24250 11000 | 28660 13000 | 28660 13000 | 33070 15000 |

| Load Belt Width (in, mm) | 31.5 800 | 35.43 900 | 41.9 1065 | 41.9 1065 | 47.2 1200 | 47.2 1200 | 47.2 1200 | 55.1 1400 |

| Load Belt Length (in, mm) | 326.8 8300 | 393.7 10000 | 407.5 10350 | 462.6 11750 | 439.4 11160 | 439.4 11160 | 518.1 13160 | 437 11100 |

| Load Belt Tensile Strength, PIW ( N·mm ) | ≥1250 N·mm | |||||||

| VertiLift Dimensions, L×W×H (in, m) | 241×120×429 6.13×3.05×10.9 | 276×124×472 7×3.15×12 | 287×130×488 7.3×3.3×12.4 | 287×130×520 7.3×3.3×13.2 | 305×138×512 7.76×3.5×13 | 305×138×514 7.76×3.5×13.05 | 305×138×555 7.76×3.5×14.1 | 315×139×518 8×3.54×13.15 |

| Shipping Size, L×W×H (in, m) | 429×87×102 10.9×2.2×2.6 | 472×91×106 12×2.3×2.7 | 488×103×120 12.4×2.62×3.05 | 520×103×120 13.2×2.62×3.15 | 512×104×124 13×2.65×3.15 | 514×14×124 13.05×2.65×3.15 | 555×104×124 14.1×2.65×3.15 | 518×108×128 13.15×2.75×3.25 |

| Shipping Weight (lb, kg) | 50710 23000 | 57320 26000 | 77160 35000 | 80470 36500 | 90390 41000 | 101410 46000 | 103620 47000 | 114640 52000 |

| Concrete Base size, L×W×H (in, m) | 295×89×15.7 7.5×2.25×0.4 | 315×91×15.7 8×2.3×0.4 | 335×101×15.7 8.5×2.57×0.4 | 335×101×15.7 8.5×2.57×0.4 | 354×103×15.7 9×2.61×0.4 | 354×103×15.7 9×2.61×0.4 | 354×103×15.7 9×2.61×0.4 | 354×108×17.3 9×2.8×0.44 |

| Concrete Base weight (lb, kg) | 23150 10500 | 26460 12000 | 28000 12700 | 28000 12700 | 33070 15000 | 33070 15000 | 33070 15000 | 35270 16000 |

| Working Ambient Temperature(℉, ℃) | -40 to +140 -40 to +59 | |||||||

| Automatic Braking System | Optional | Optional | Yes | Yes | Yes | Yes | Yes | Yes |

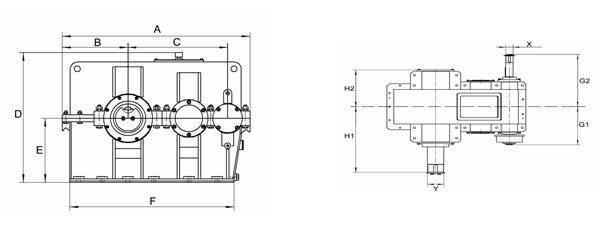

Gear Reducers

| A | B | C | D | E | F | H1 | H2 | G1 | G2 | X | Y | |

| 320 (mm/in) | 1600 63 | 560 22 | 850 33.5 | 1136 44.7 | 560 22 | 1400 55.1 | 945 37.2 | 388 15.3 | 548.5 21.6 | 754 29.7 | 85 3.35 | 180 7.1 |

| 456 (mm/in) | 1840 72.4 | 630 24.8 | 1000 39.4 | 1150 45.3 | 600 23.6 | 1500 59 | 975 38.4 | 593 23.3 | 627.5 24.7 | 808 31.8 | 95 3.74 | 190 7.48 |

| 640 (mm/in) | 1950 76.8 | 665 26.2 | 1000 39.4 | 1195 47 | 620 24.4 | 1460 57.5 | 1360 53.5 | 900 35.4 | 700 27.6 | 885 34.8 | 95 3.74 | 220 8.66 |

VertiLift Gear Reducer Advantages

1. The double circular arc gear reducer, smooth transmission, low noise and vibration, whose bearing capacity, wear resistance, contact fatigue life and temperature rising are better than that of the common involute gear, is more suitable for pumping unit with low-speed, overloading and continuous working condition.

2. The gear reducer housing is made of high quality steel plate welding and leakage test will be carried; compared with the casting housing, the bearing capacity is larger and strength is higher.

3. The gear reducer output shaft is made of alloy steel and nondestructive detection will be conducted, meanwhile, the distance of two supporting points distance widened to better adapt to the reducer cantilever stress structure and improve the strength & bending capacity.

4. The gear reducer adopts external-contacting braking, convenient adjustment and has reliable braking effect. In addition, we can also provide a set of automatic braking system according to user requirements.

Main Advantages of VertiLift Pumping Unit

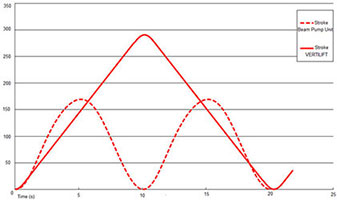

1. Long, Slow Strokes: Long strokes lead to high pump fill and less fluid impact; Slow SPM means less wear on down-hole equipment and less operational cost.

1. Long, Slow Strokes: Long strokes lead to high pump fill and less fluid impact; Slow SPM means less wear on down-hole equipment and less operational cost.

2. Belt Transmission: Power is transmitted by a long life heavy-duty belt, whose elastic cushion effectively absorbs impact in reverse action and results in a uniform reciprocal movement of the rod string.

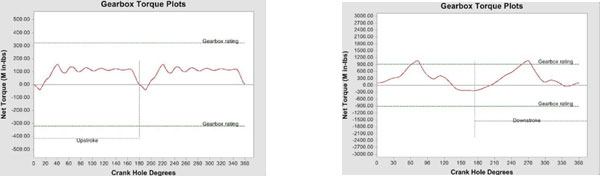

3. Low Torque Demand: The torque demand is greatly reduced. Therefore, smaller prime mover and gear box is possible, which can cut down energy costs by 10% to 30% compared to other manual lift systems.

4. Adopt Symmetrical Balance, Mechanical Balance. The counterweight can be adjusted simply and conveniently.

5. Safe and Easy Operation due to Optimum Structure Design: Two sets of brake systems with the automatic braking device ensure the units absolute safety; enclosed unit design allows the unit to be folded up for convenience during shipping and allows it to be moved safely.

6. High Reliability and Minimum Maintenance: The antifriction bearings, a long life belt and heavy load roller chains are adopted to ensure unit reliability. The optimized lubrication system and automatic protective device as well as the enclosed unit can reduce the frequency of repairs and maintenance.

6. High Reliability and Minimum Maintenance: The antifriction bearings, a long life belt and heavy load roller chains are adopted to ensure unit reliability. The optimized lubrication system and automatic protective device as well as the enclosed unit can reduce the frequency of repairs and maintenance.

7. Fairly Complete Production Supporting System. The system ensures the unit can be used with big pumps for more fluid lift and small pumps in deep well applications.

Applications of VertiLift Pumping Unit

As a patent products, VertiLift is a 100% mechanical driven pumping unit. It is especially suitable for using with big pumps for more fluid lift, small pumps in deep wells and also heavy oil recovery applications. Now VertiLift pumping units have been expanded to 8 models, and the maximum peak polish rod loads range from 22,046 lbs to 57,320 lbs and strokes from 197 inch to 354 inch. Equipped with advanced technology, the pumping unit always brings good economic benefits to clients by offering highly efficient, reliable, safe performance both at home and abroad.

1. Substituting Electric Submersible Pumps. Matching φ70~φ120 large pump, the pump depth of the pumping unit can achieve 1500~2700m, the theoretical liquid producing capacity is 550 cubic meters per day.

2. Using Small Pumps to Pump Deeply. Mating φ32~φ44mm small pumps, the pump depth of the pumping unit can achieve 4000m.

3. The Exploitation of Heavy Oil Wells. According to the user’s program of special oil wells, the units can configure the automatic control system based on oil well loading changes to adjust the real-time speed and the real-time stroke. Mating the oil recovery processes like hollow rod electric heating, mixing light oil, water, SAGD and so on.

4. Application of Cluster Wells. These wells give full play to the advantages of the compact structure and the small areas of the pumping units. They are widely used in artificial islands, residential areas, cluster well sites and other restricted areas.